What type of Skin Packaging Machine is right for you?

The process is straightforward. The plastic is unwound from a roll, then held in place by a clamping frame over a sheet of adhesive-coated paper with the product placed on the paper. The sheet of skin packaging plastic film is heated until it becomes pliable, usually by measured by timer or infrared sensor.. The clamping frame is lowered to the paper and the flexible plastic is drawn down by vacuum onto the paper and product. Wherever the hot plastic touches the paper, it activates the adhesive and bonds the two together.

While the basic processes are the same for every machine, the mechanisms that produce them can vary significantly. There are machines available for every budget and production requirement. Here are a few options:

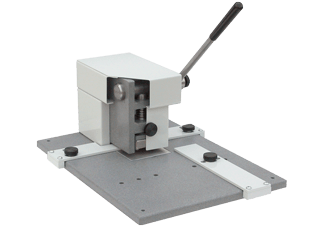

Fixed Oven – Manual Frame Operation

This is a typical budget model – The oven is fixed in place and only hot during the heating cycle. The film frame is moved from the oven to the paper manually by means of a pull down handle. These machines typically load the film from the back of the machine, and the finished cycle is pulled toward the operator. These machines are typically “Table Top” designs and run paper either 12” X 18” or 18” x 24”.

Fixed Oven – Semi Auto Operation

By a wide margin, this has been the most popular style of skin packaging machine. The oven is fixed in place directly above the platen that holds the substrate. When the heat cycle is finished, and air cylinder releases and the frame and plastic drop down over the product and paper. After the cycle has been completed and finished board is removed, a push of a button raises the film frame back into it’s starting position. These machines are available in standard sizes of (in inches) 18X24, 34X30, 24X36, 30X36, 36X48 and custom sizes.

Moving Oven – Semi Auto Operation

The moving oven machine operates similarly to the fixed ovens in all aspects except the oven travels forward and backward during the cycle. Because the oven is always on, the cycle times are shortened because there is no need to wait for the oven to warm up. Another benefit is that the product is easier to load in the machine because the oven has been removed from directly above the sheet which makes it easier to see. There are a few drawbacks too. For example, because the oven is always on, it draws more power and generates more heat. On average, the machines also take up about twice the space of a fixed oven machine.

Fully Automatic Inline Machines

When high production is needed, an inline skin pack machine is the solution. This machine uses belts to automatically move the paper and product from the loading area to the packaging station and then out. They can even be integrated with an inline die cutter for high production efficiency. These machines are fast but require a dedicated operator to keep them running smoothly and properly set up.

Skin Packaging Machinery - Why buy from us?

All skin packaging machinery is not created equal. Depending on your needs, you might want a manual, semi-automatic or even a fully automatic machine line. You probably don’t know the options, the styles or the possibilities. However, we do and we will be happy to talk you through the process of finding the right machine for your needs.

Find the Right Machine for Your Needs

While most packaging machinery operates more or less the same, there are some differences that may not be obvious. We will help guide you to the perfect machine for you, even if you don’t buy it from us. Contact us to learn more.

A Few Companies We Represent