What type of Skin Packaging Machinery is right for your product?

Skin packaging machinery is used to package small parts and manufactured products using heat and vacuum to form film tightly over the product and bond it to a skin board which has been coated with an adhesive. The operator unwinds plastic from a roll, which is then held in place by a clamping frame over a sheet of adhesive-coated paper, known as skin board, with the product placed on the paper. The sheet of skin packaging plastic film is heated until it becomes pliable. The clamping frame is lowered to the paper and the flexible plastic is drawn down by vacuum onto the paper and product. Wherever the hot plastic touches the paper, it activates the adhesive and bonds the two together.

While the basic processes are the same for every machine, the mechanisms that produce them can vary significantly. There are machines available for every budget and production requirement. Here are a few style options:

A word about pricing skin pack machines

We believe in giving as much information as possible, so we’re providing rough estimates about pricing for you to ballpark your costs. There are other factors such as machine size, freight, options etc that can change the costs, so please use these prices as a ballpark tool, not an actual quote.

Skin Packaging Machine Sizes –

While custom sizes are available for just about any Product, skin packaging machines for the most part come in standard sizes. These sizes correspond with commonly available sizes of boards and film.

Skin Packaging Machine Sizes

12″ × 18″ (manual only)

18″ × 24″

24″ × 30″

24″ × 36″

30″ × 36″

36″ × 48″

40″ × 48″

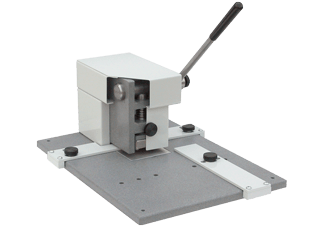

Fixed Oven Skin Packaging – Manual Frame Operation

A fixed oven manual skin packaging machine is a good economical solution for low-volume packaging. The oven heats only during the cycle, and the operator manually moves the film frame over the product using a pull-down handle. They can run the same volume as other fixed oven machine, but with more operator effort. These tabletop machines typically run 12” × 18” or 18” × 24” boards and are commonly loaded from the rear, with finished packages removed from the front.

Typical starting price: ~$6,500

👉 Learn more about manual skin packaging machines

Fixed Oven Skin Packaging – Semi Auto Operation

Fixed oven semi-automatic machines are far and away the most popular style of skin packaging machinery. The oven is fixed above the platen, and once heating is complete, an air cylinder automatically lowers the film over the product and board. After packaging, the frame returns to its starting position at the push of a button, improving consistency and operator efficiency. Available in sizes 18 X 24 and larger

Typical starting price: ~$7,500

👉 Explore semi-automatic skin packaging machines

Moving Oven Skin Packaging – Semi Auto Operation

Moving oven skin packaging machines operate similarly to fixed oven systems, but the oven travels during the cycle and remains continuously heated. This shortens cycle times and improves throughput, visibility and loading access for the operator. Tradeoffs include higher electric use, increased heat output, and a 2X larger machine footprint compared to fixed oven models.

Typical starting price: ~$9,000

👉 View moving oven skin packaging machines

Fully Automatic Inline Skin Packaging Machines

Fully automatic inline skin packaging machines are designed for high-volume production environments with dedicated items. These systems can automatically transport product and board through the packaging cycle and can be integrated with inline die cutting for maximum throughput. While highly efficient, they require experienced setup and operation to maintain optimal performance as well as dedicated tooling for all items

Typical starting price: ~$200,000+

👉 Learn about automatic skin packaging systems

| Machine Type | Operation | Estimated Production | Typical Board Sizes | Pros | Cons | Starting Price (est) |

|---|---|---|---|---|---|---|

| Fixed Oven - Manual | Manual Frame Movement | 25 boards / Hour | 12X18, 18X24 | Lowest cost, simple operation, compact tabletop design | Slower cycle times, more operator involvement, fewer sizes available | $6,500 |

| Fixed Oven Semi-Auto | Air cylinder drop and lift | 40 boards / Hour | 18X24, 24X30, 24X36 | Most popular style, consistent results, reduced operator effort | Slightly higher cost than manual, requires compressed air | $7,500 |

| Moving Oven - Semi-Auto | automatic oven movement | 50 boards / Hour | 18X24, 24X30, 24X36 | Faster cycles, improved loading visibility | Higher power use, larger footprint | $7,500 |

| Fully Automatic | Fully Automatic | 100 boards / Hour | 18X24,24X30 | Maximum throughput, inline die-cut integration | High cost, requires experienced setup | $200,000 + |

Skin Packaging Machinery - Why buy from us?

All skin packaging machinery is not created equal. Depending on your needs, you might want a manual, semi-automatic or even a fully automatic machine line. You probably don’t know the options, the styles or the possibilities. However, we do and we will be happy to talk you through the process of finding the right machine for your needs.

Find the Right Machine for Your Needs

While most packaging machinery operates more or less the same, there are some differences that may not be obvious. We will help guide you to the perfect machine for you, even if you don’t buy it from us. Contact us to learn more.

A Few Companies We Represent